Innovations that can be seen immidiately. Our R&D department works closely together with our Prototype Construction Unit.

Introduction

Research and development are two mutually inclusive processes in the industry.

The result of research and development conducted by engineers of R&D results in the development of new products, but also in the modernization of pre-existing solutions.

Our activities include the design, construction and testing of new medical solutions, as well as improving pre-existing products. If the newly created product meets all legal requirements and regulations concerning medical devices, it will be implemented into production.

We use programs that give us the freedom to design and test different solutions, while maintaining the precision needed in bioengineering - including Solid Edge and NX CAM.

Achievements

Over the past two years since the establishment of the department in 2014 we have already handed in 5 applications to patent offices.

We are currently working on five projects of medical instruments.

Technology and equipment

We can construct prototypes of products in our Prototype Construction Unit, through the use of the following technologies:

-

Conventional turning and milling

During milling the main movement is the rotation of the tool on its axis. The workpiece performs primarily feed motion.

-

Wire Electrical Discharge Machining (WEDM)

WEDM uses a metal wire as the tool-electrode, in order to obtain the desired shape of the workpiece by cutting it.

-

Electrical Discharge Machining (EDM)

EDM is a manufacturing process that uses electrical discharges between two electrodes (tool-electrode and workpiece-electrode) separated by a dielectric liquid, to cause the erosion of the material.

-

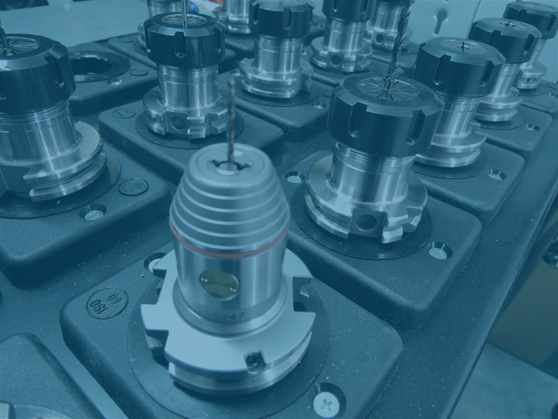

CNC milling

Computer numerical control milling is used for materials processing. It allows fast, precise and highly repeatable construction of complex shapes.

-

Tungsten inert gas (TIG) welding

This method of welding uses non-consumable tungsten electrode in inert shielding gas. This results in a bigger heat release at the weld area, and in less strain on the tungsten electrode.

-

Laser beam welding (LBW)

This type of welding provides robust welds and is performed in inert shielding gas or, if the material that is being welded does not oxidize, in open air.

In the near future we plan to buy more machines, such as EDM machine, wire EDM machine and a lathe. Then the range of our services will significantly expand.